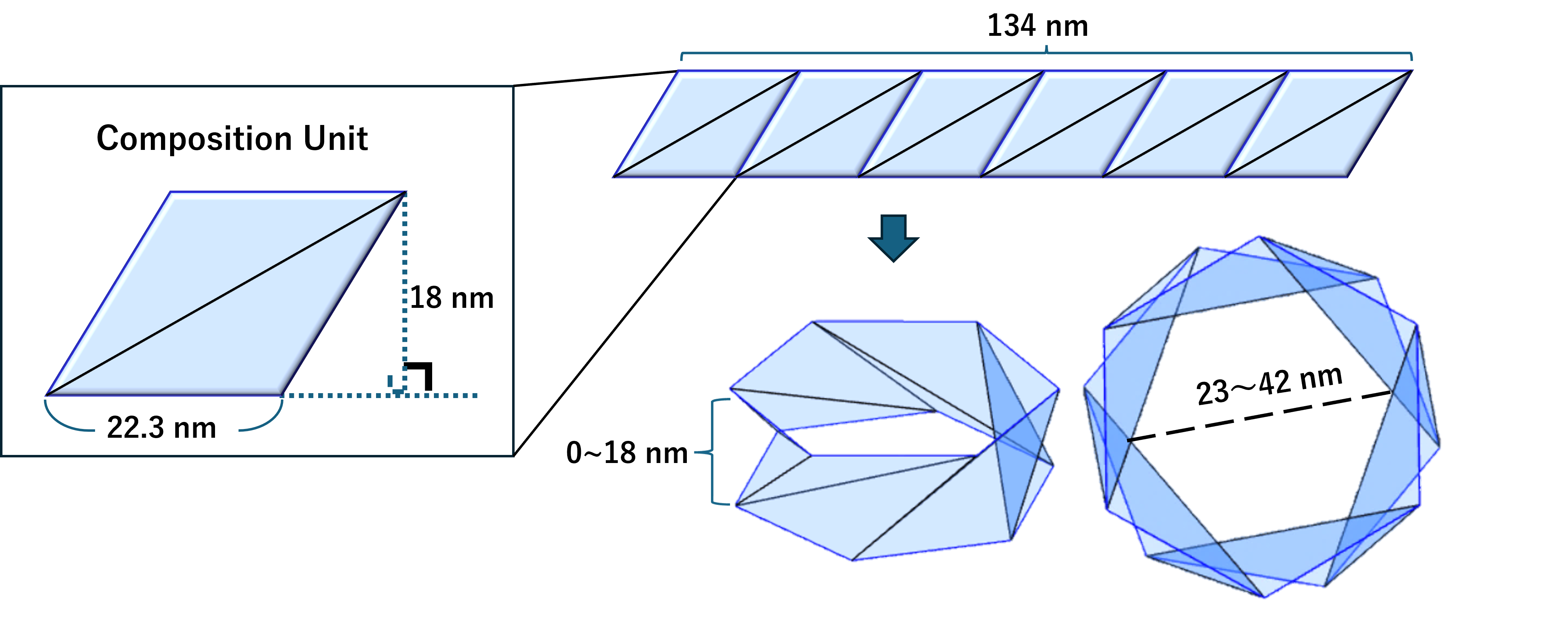

Determining the aspect of the structure

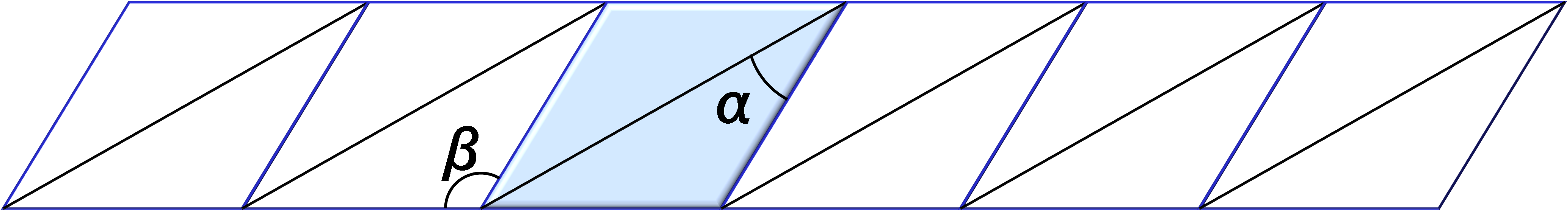

Figure 1. The basic dimensions of KIT-D

This figure shows the dimensions of the KIT-D structure. It is made

of a series of six parallelograms composed of two isoceles triangles

which are placed back to back. The parallelogram unit can be rolled

up into a tubular structure with height ranging from nearly 0 to 18

nm, and its inner diameter changing from 23 to 42 nm.

Two-layered structure to enhance rigidity

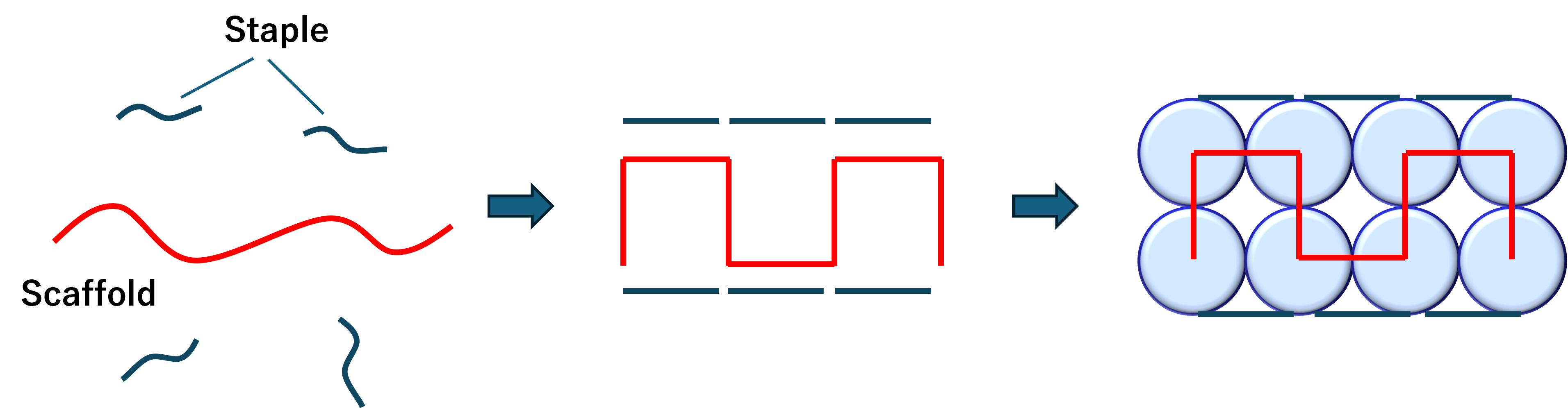

Figure 3. Formation of the two-layered structure

Staple strands were designed to fix the scaffold strand in a

meandering way to form two layers, providing durability to the

structure.

Adjusting the length and position of the hinges

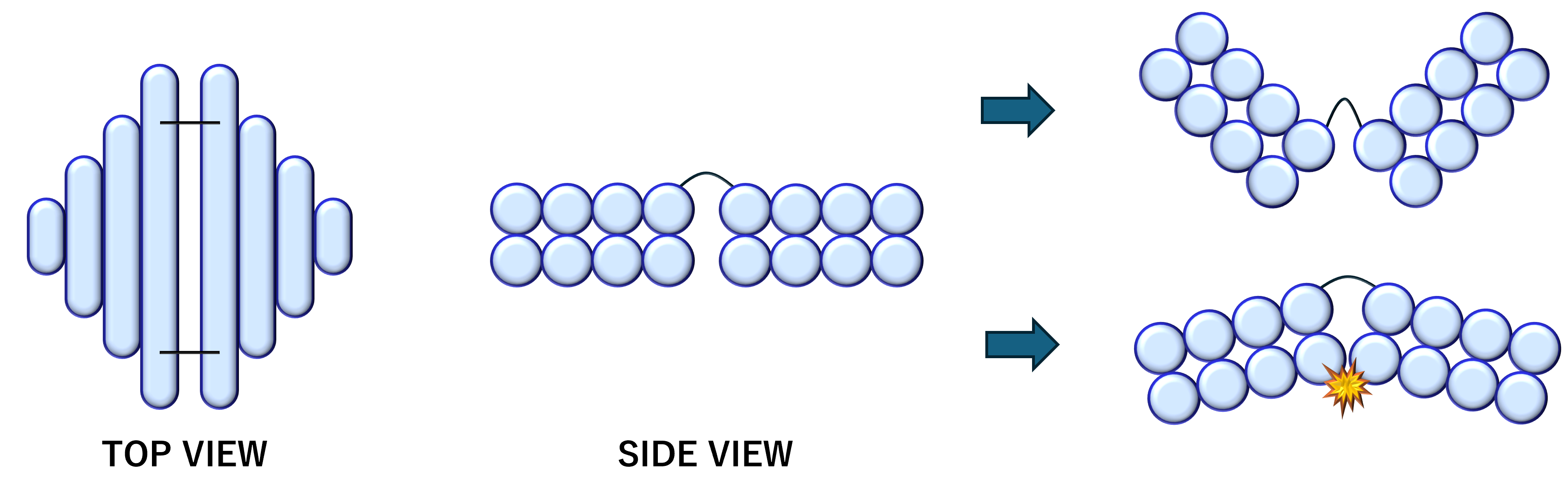

Figure 4. Positioning of the hinges to guide folding direction

Hinges were located on one side of the layer to navigate the

direction of the folding, enabling the implementation of mountain

and valley folds in desired positions.

Structural Design for Transformation

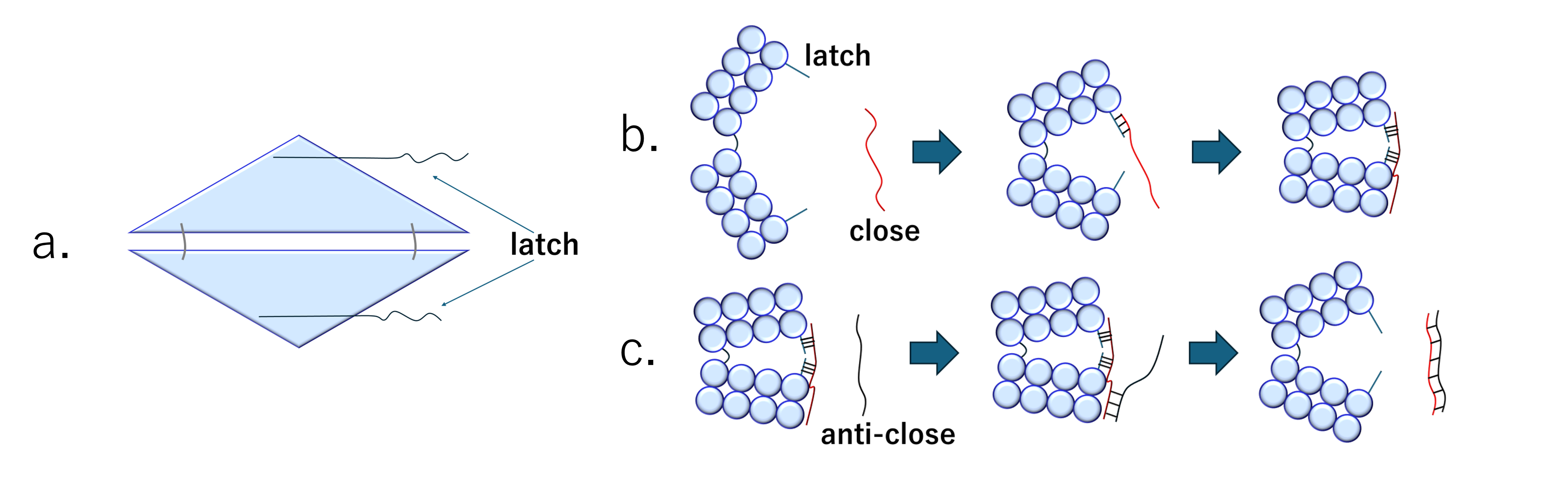

Figure 5. Positioning of latches and transforming mechanism

5a. shows that the latches are located at the tips of the

triangles.

5b. illustrates how KIT-D closes when an additional strand “close”

is added.

5c. shows the transformation of the structure to its open state when

”anti-close” is added.