Background and problems

Background

Recent advancements in precise structural control at the nanoscale

have rapidly progressed, particularly through the use of DNA origami

technology , which allows for the precise construction of structures

with specific shapes and functions tailored for various applications,

such as molecular transport, sensing, and filtration devices [1]. DNA,

through the Watson-Crick base pairing mechanism, self-assembles with

nanometer-level precision. Chemical modifications and functional

molecules can also be incorporated into the design, underscoring the

potential of this field of research.

DNA origami technology [2] is composed of a single long DNA strand (scaffold) and auxiliary strands (staples) that fold the scaffold. By leveraging sequence complementarity, this method enables the creation of intricate two- and three-dimensional shapes. The rigidity and stability of the structures can be controlled by adjusting the number and arrangement of staple strands.

Currently, a variety of structures utilizing DNA origami have been proposed, such as functional molecular robots [3], DNA-based logic circuits that operate as electrical alternatives [4], and cylindrical structures like nanopores, which serve as the foundation for this study. These structures hold great potential for applications in engineering and pharmaceutical research.

Nanopores refer to small channels or tubular structures on cell membranes, typically measuring several nanometers in size, and have been applied in sequencing technologies and analytical methods [5]. Recently, dynamic DNA nanopores have been reported, which enable the control of permeable substances by altering the pore diameter.

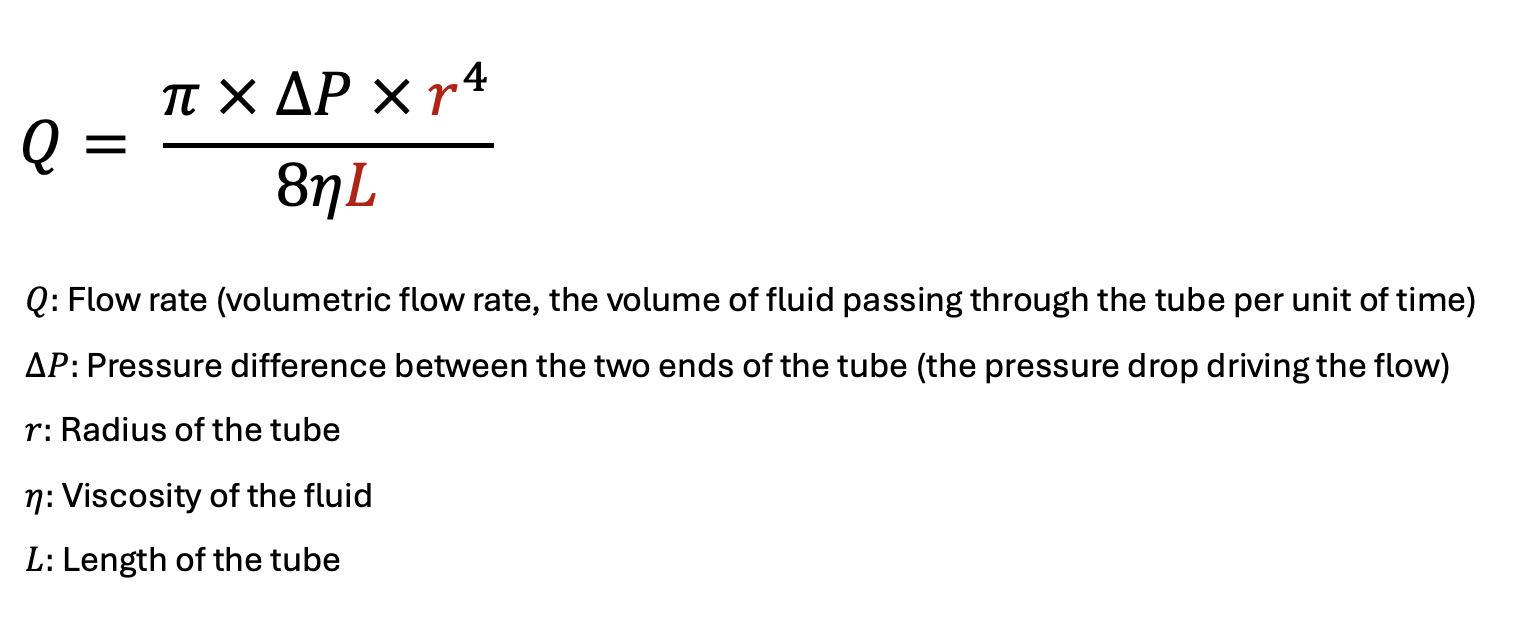

In general, the flow rate through narrow tubular structures like nanopores is defined by Poiseuille's Law[6]. According to this law, the volume of fluid flowing per unit time is proportional to the radius of the pore and inversely proportional to the length of the tube. Although novel DNA nanopores capable of dynamically controlling both the pore radius and tube length hold promise for unprecedented applications, they have yet to be realized.

DNA origami technology [2] is composed of a single long DNA strand (scaffold) and auxiliary strands (staples) that fold the scaffold. By leveraging sequence complementarity, this method enables the creation of intricate two- and three-dimensional shapes. The rigidity and stability of the structures can be controlled by adjusting the number and arrangement of staple strands.

Currently, a variety of structures utilizing DNA origami have been proposed, such as functional molecular robots [3], DNA-based logic circuits that operate as electrical alternatives [4], and cylindrical structures like nanopores, which serve as the foundation for this study. These structures hold great potential for applications in engineering and pharmaceutical research.

Nanopores refer to small channels or tubular structures on cell membranes, typically measuring several nanometers in size, and have been applied in sequencing technologies and analytical methods [5]. Recently, dynamic DNA nanopores have been reported, which enable the control of permeable substances by altering the pore diameter.

In general, the flow rate through narrow tubular structures like nanopores is defined by Poiseuille's Law[6]. According to this law, the volume of fluid flowing per unit time is proportional to the radius of the pore and inversely proportional to the length of the tube. Although novel DNA nanopores capable of dynamically controlling both the pore radius and tube length hold promise for unprecedented applications, they have yet to be realized.

Formula 1: Poiseuille's Law.

It describes the flow rate of a viscous fluid (such as water or air) through a narrow cylindrical tube.